Co-authored with Donald G. Parent, PE

Two prior articles tell the story of how a combination of unique winter weather, improper facility maintenance, and a heat cable failure, resulted in a slip-and-fall accident and injury. The first article introduced the building failure evidence obtained at a site inspection and the development of a 3D reconstruction that illustrated the context of that evidence. The second article described the sequence of weather events and component failures that created the hazardous conditions that caused the accident. In this month’s article, we discuss how the Finite Element method was used to validate our conclusions.

Hypothesis and Confirmation

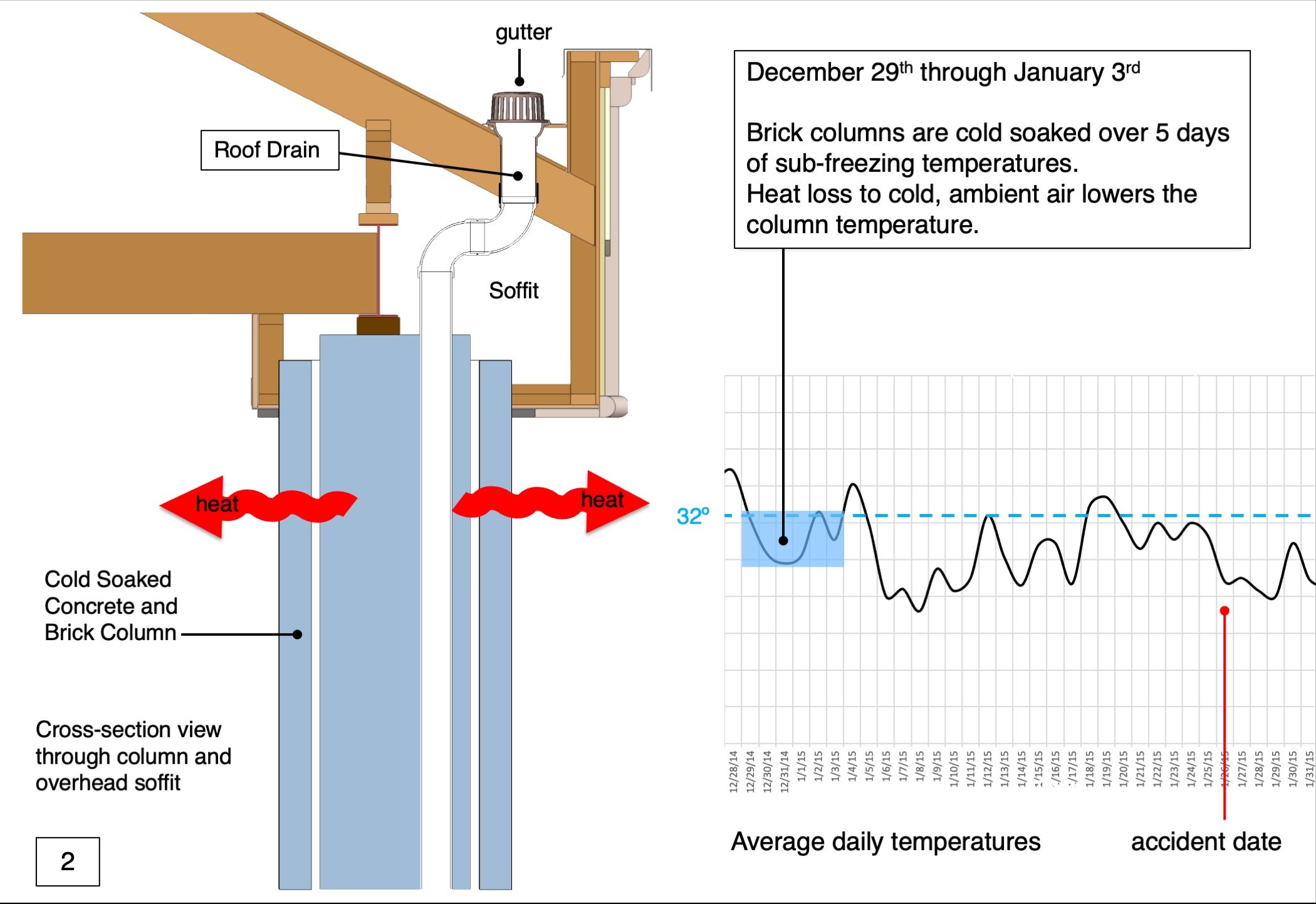

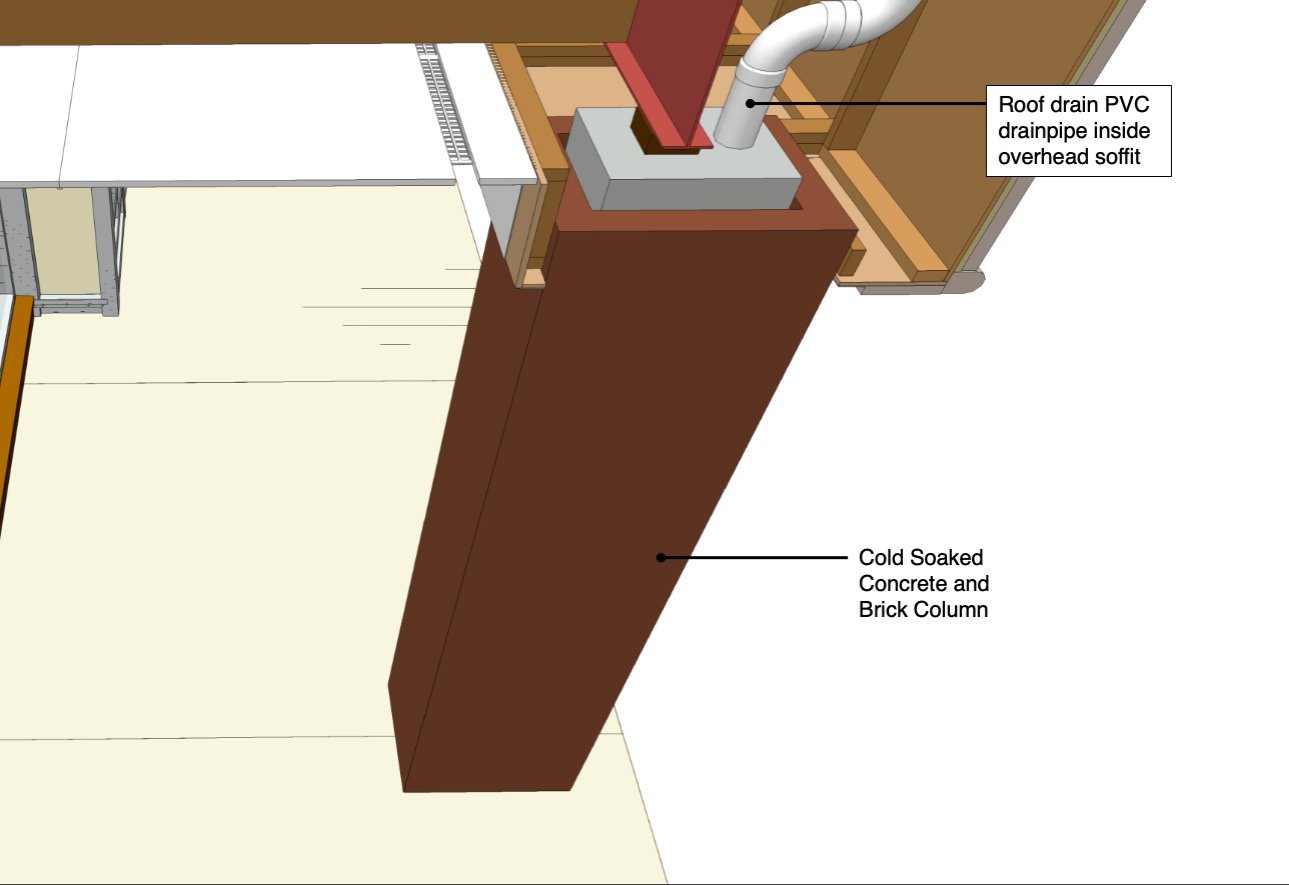

A slip and fall injury on an icy parking lot during the winter of 2015 caused a serious injury. That winter presented an unusual mix of both warm and cold temperatures and rainy conditions. The cold spells from that season were unique in both their magnitude and duration. Frozen pipes and other types of structural damage were common occurrences. An investigation of the accident site revealed that the roof drain heat tape was not functional and internal PVC roof drain components had fractured. We hypothesized that freezing weather conditions had caused an ice plug to form in a lower part of the roof drain resulting in rainwater accumulating above. A subsequent cold spell froze the accumulated water and fractured the PVC pipe. A subsequent rainstorm caused water to leak from the fractured pipe into the roof structure and flow onto the parking area.

We hypothesized that unique weather conditions and a heat tape failure were both necessary for creating conditions where water would move through the building structure and then accumulate and freeze on the parking surface. To prove our hypothesis, a thermal Finite Element Analysis (FEA) of the support column and its internal roof drain was generated. The FEA of the support column and roof drain combined our 3D computer model of the building geometry with multiple days of weather history obtained from the National Weather Service. The result was a time-based determination of the temperature behavior of the concrete and brick column and PVC roof drain. This analysis confirmed that the temperature change inside the support column was sufficient to create an ice plug in the roof drain.

What is Finite Element Analysis?

FEA is a computer-based method for determining the behavior of physical objects under mechanical and/or thermal loads and external boundary conditions. FEA is a well-established engineering tool that breaks up solid objects into hundreds or thousands of sub-elements and computes the interactions of each sub-element with its adjacent neighbor. The sub-elements located at the object's boundaries (its edges) interact with their local ambient conditions. For our time-based thermal analysis, these interactions were the varying heat transfer conditions during the analysis period. The result was a temperature history of the concrete and brick column during the period of the analysis.

What Did the FEA Show?

The initial cold period shown in the weather history data caused thermal energy (heat) to flow from the brick and concrete column to the cold outside air, lowering its temperature to well below freezing. This was followed by a brief warm spell and a brief rainstorm. When draining water from the rainstorm flowed into the PVC roof drain, the inner surface of the roof drain remained cold enough for sheets of ice to build up and create an ice plug. Re-running the FEA with heat output from the heat tape showed that the internal downspout temperature would not have fallen below freezing during the initial cold spell. Consequently, an ice plug would not have formed in the roof drain and the accident would not have occurred.

Conclusion

The FEA model effectively supported and confirmed the engineering and weather data analysis by demonstrating that the thermal history of the concrete and brick column combined with the failure of a heat tape would cause solid ice to form in the roof drain.

CO-AUTHOR NOTE:

Donald G. Parent is a licensed professional engineer (PE) with more than 35 years of experience in the design and analysis of mechanical and electrical products and systems. Mr. Parent provides engineering consulting and expert witness services relating to product design, process development, and product launch, as well as patent and intellectual property-related matters. He has been deposed and testified as an expert in product design, product safety, and intellectual property cases.